This is an introduction to Takazudo's DIY series product, zudo-block-60 Open.

The zudo-block-60 Open is a 60HP Eurorack frame with minimal construction for module mounting. Using 3D-printed rails, it has no built-in power supply or enclosure but is very affordable. Side panels and aluminum plate frames assemble easily with screws. It's convenient for getting started with modular synths or testing DIY modules.

Side panels are available in two types: the rectangular A-type and the stepped B-type, which allows the rails to be tilted at a steeper angle.

This product is available for purchase below.

Product Photos

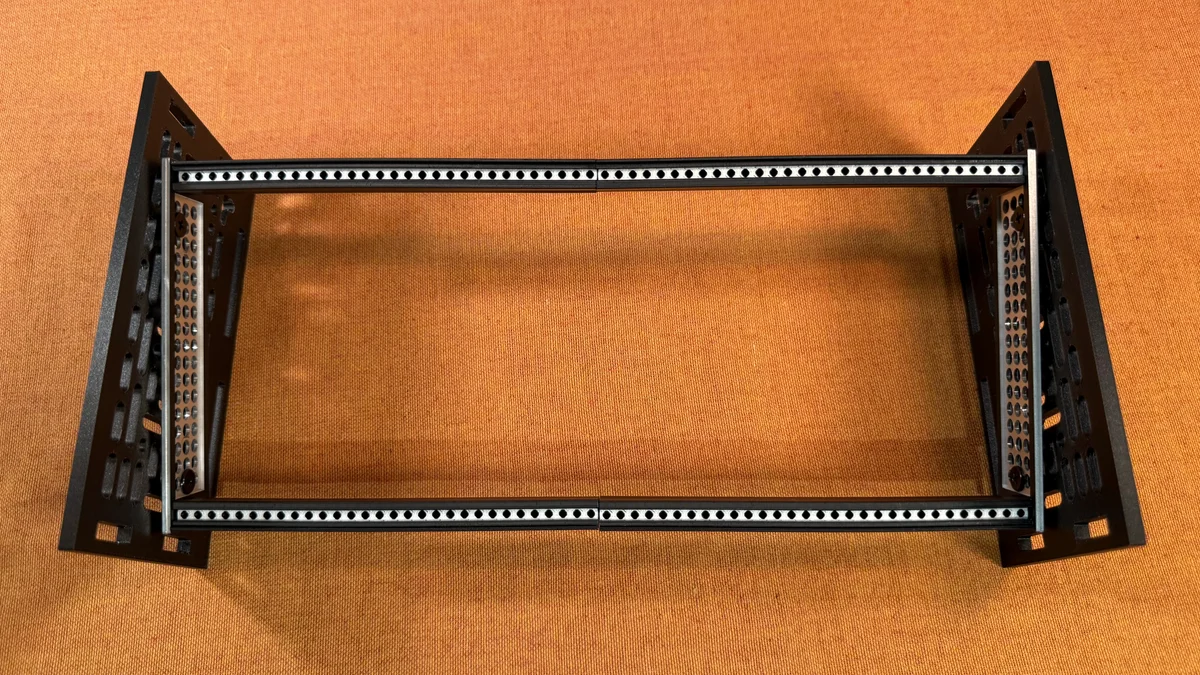

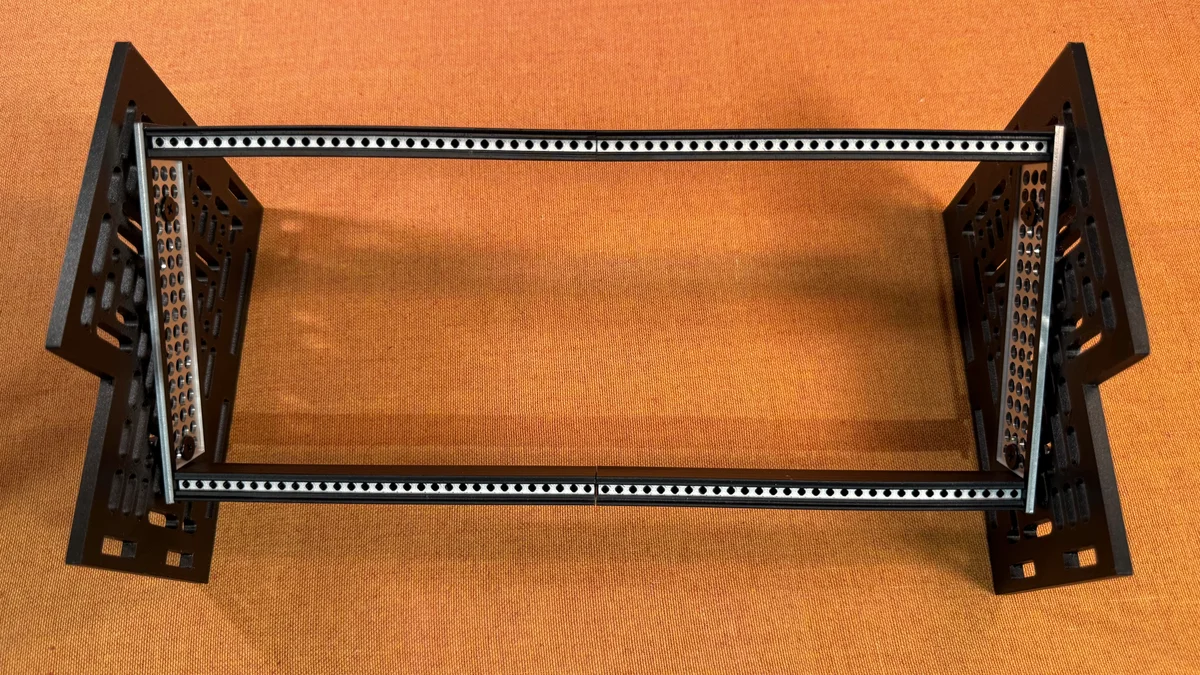

A-Type (Rectangular Side Panels)

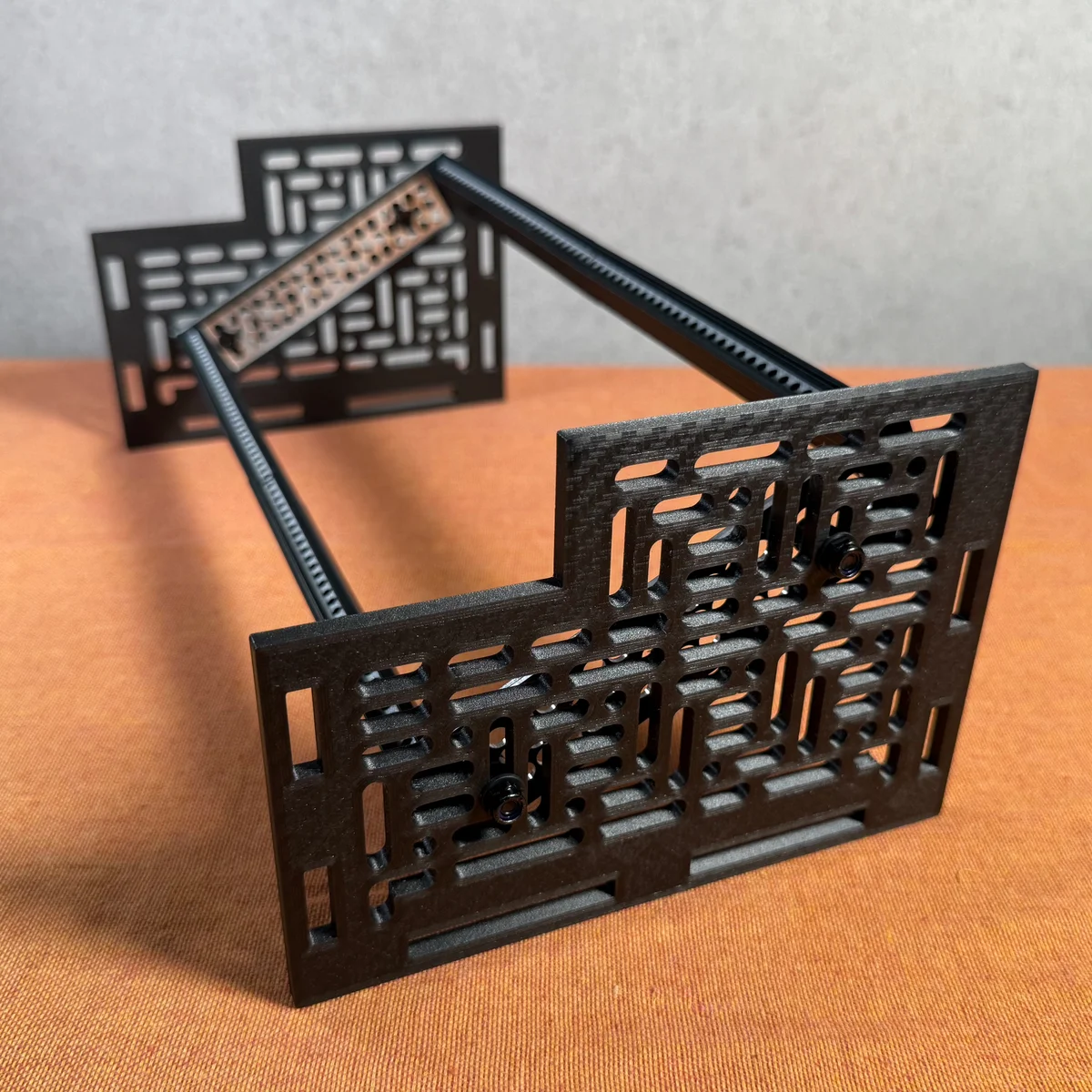

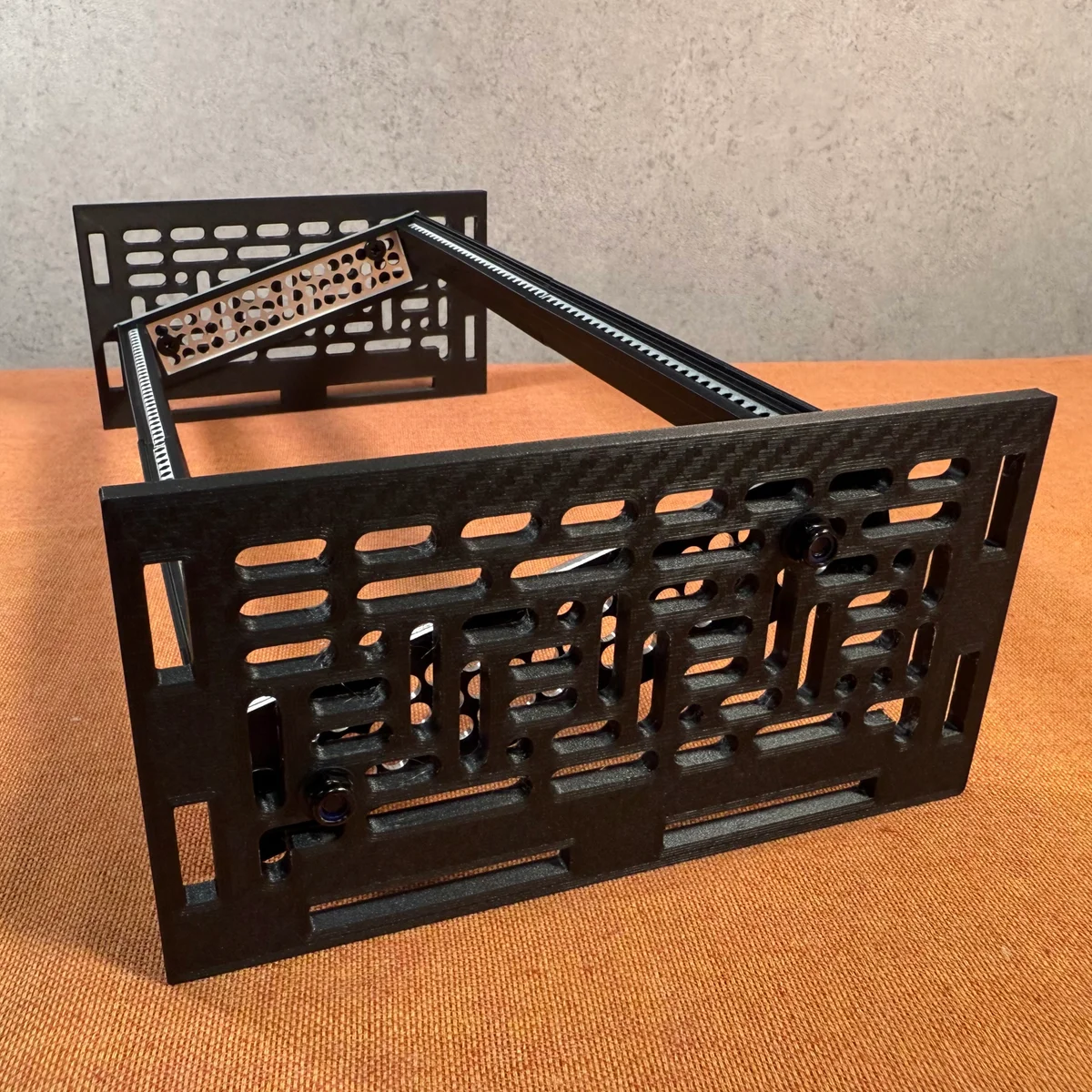

B-Type (Stepped Side Panels)

About zudo-block-60 Open

One of the challenges when getting started with modular synths is choosing your first case. If you're planning to assemble a substantial collection of modules from the start, a large case is likely the best choice. But when you just want to try out a module or two that caught your eye, few people can make that kind of commitment right away. And even small modular synth cases can be quite expensive. That's where the zudo-block-60 Open comes in as a great option.

About Power Supply

このケースには電源が内蔵されていないため、別途電源をご用意頂く必要があります。電源用のモジュールとして、以下の3つを国内で入手しやすいものとしてご紹介しておきます。

また、電源ってどう考えれば良いのかよく分からないという方向けに、以下コラムを別途用意してあります。こちらも併せてご参照頂けますと幸いです。

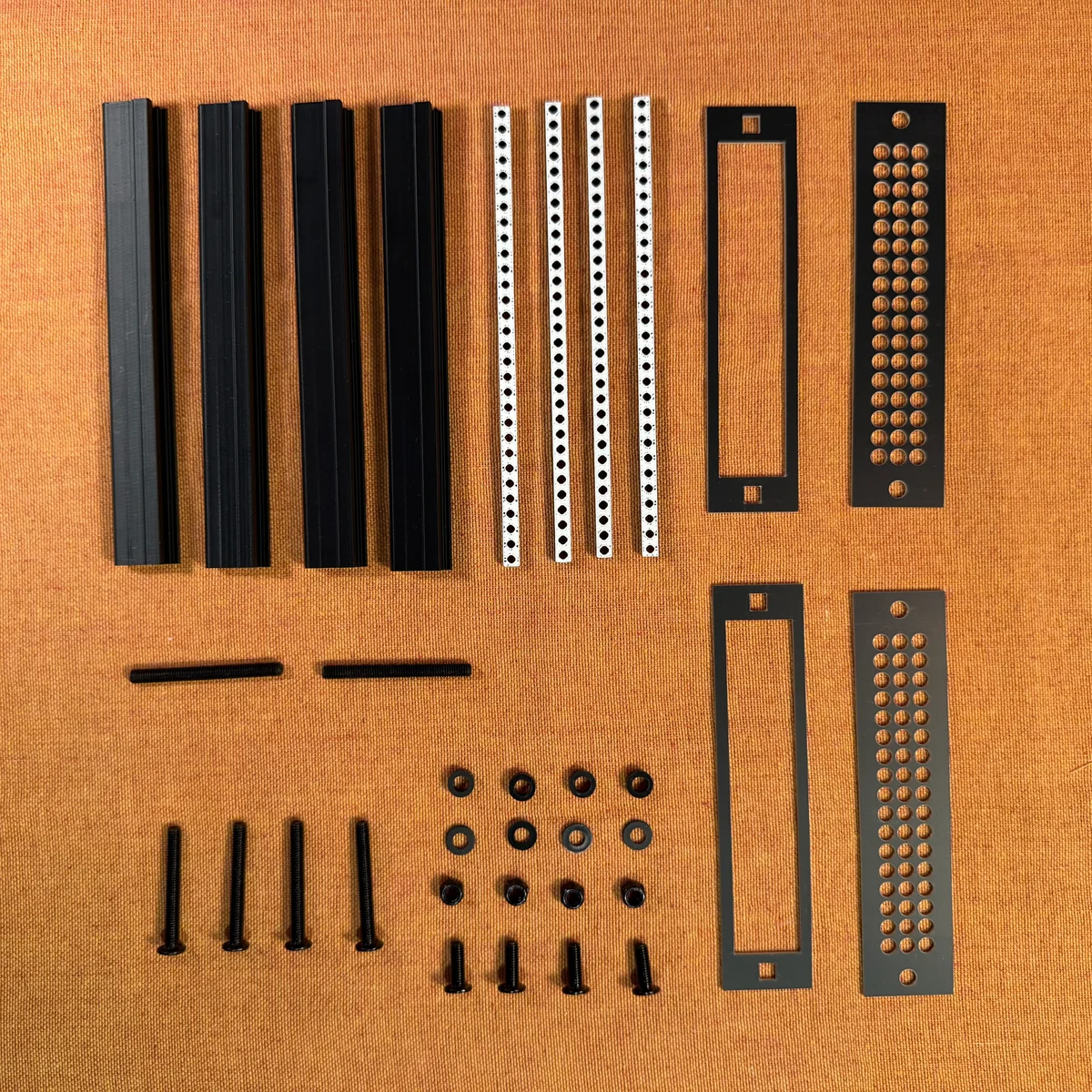

Included Items

- Side panels: 2

- Rail mounting aluminum panels: 1 set

- ASA rails 30HP (152.5mm): 4

- ASA bar nuts 30HP (152.5mm / M3 holes): 4

- M5 screws 14mm: 4

- M5 screws 40mm: 4

- M5 set screws 50mm: 2

- M5 lock nuts: 4

- 1mm spacer washers: 4

- 3mm spacer washers: 4

About the Rails

The zudo-block-60 Open uses plastic rails, which have both advantages and disadvantages. The advantage is that they are affordable. The disadvantages are that they are prone to wear and require a screwdriver to tighten screws. To prevent wear and ensure long-term use, please avoid overtightening screws. Please keep these points in mind when using the product.

When building a case, one of the biggest challenges is the cost of rails. I tried purchasing directly from manufacturers that other modular synth case makers use, and also got quotes for custom metal cutting based on my own drawings, but solidly built metal rails inevitably come at a certain price. At the same time, I personally didn't like slide nuts.

After much trial and error, I tried making plastic rails with a 3D printer and they turned out surprisingly usable. Since these are overwhelmingly more affordable, I refined the design and decided to sell it as this frame kit.

These rails, particularly the bar nut portion, have been carefully engineered despite being plastic.

First, as you can see, the bar nuts are considerably taller than standard metal bar nuts. This design was settled on to ensure screws can be securely fastened. Since plastic is softer, if the bar nuts were the same height as metal ones, the holes would wear out quickly and screws would no longer hold.

Additionally, the screw holes are made slightly smaller than the M3 screw diameter and with a slightly irregular shape. This is so that when you drive a screw in, threads are naturally formed in the plastic. Because of this design, hand-tightened screws require considerable force. Therefore, when using these rails, you'll generally need to use a screwdriver to fasten screws. We appreciate your understanding on this point.

After testing various plastic materials, I settled on ASA (Acrylonitrile Styrene Acrylate). If the material is too hard, making the holes smaller would prevent screws from going in at all, and even if they did, the holes would chip. If it's too soft, screws would pull out easily. After extensive testing, ASA proved to be the right balance of hardness with sufficient flexibility.

The bar nut color is white on the top and bottom surfaces only. While all-black looks sleeker, making everything black makes it difficult to see the screw holes unless you're in a well-lit environment. So the top and bottom are white to make the screw holes visible.

Regarding rail length, I experimented with longer rails as well, but because they're plastic, if they're too long, touching the modules causes the rails to wobble, and the material's elasticity becomes noticeable. There may be room for improvement with further research, but for now, 60HP seems to be the sweet spot, which is why this product is offered in a 60HP size.

Assembly Instructions

Detailed assembly instructions with video are available in the following guide:

Assembly requires tools such as a hex key wrench, wrench, pliers, and Phillips screwdriver. Please refer to the guide above for details.

The guide provides step-by-step instructions with video, covering rail joining, side panel attachment, and more.

That concludes our introduction of the zudo-block-60 Open.

We hope you find this helpful.