CJ7912 - -12V Negative Linear Regulator

Fixed negative voltage regulator providing stable -12V output in compact TO-252-2L (DPAK) surface-mount package for negative power rail applications.

Overview

The CJ7912 is a three-terminal negative voltage regulator in TO-252-2L (DPAK) package, designed to provide a fixed -12V output from a more negative input voltage. This component serves as the final stage in the -12V power rail, converting the -13.5V DC-DC output to a clean, low-noise -12V suitable for modular synthesizer op-amp circuits and analog signal processing.

Key Specifications

| Parameter | Value | Notes |

|---|---|---|

| JLCPCB Part Number | C94173 | |

| Manufacturer Part Number | CJ7912 | |

| Package | TO-252-2L (DPAK) | Surface-mount |

| Stock Availability | 15,466 units | Moderate availability |

| Unit Price | $0.11 | JLCPCB pricing |

| Output Voltage | -12V ±4% | -11.52V to -12.48V |

| Output Current | 1.5A max | Design uses 0.8A |

| Dropout Voltage | ~2V typical | Maximum VIN = -14V |

| Line Regulation | ±0.5% typical | Input voltage variation |

| Load Regulation | ±1% typical | Output current variation |

| Ripple Rejection | >60dB | @120Hz |

| Quiescent Current | ~5mA typical | No-load consumption |

| Thermal Resistance θJC | 5°C/W | Junction to case (tab) |

| Thermal Resistance θJA | 40°C/W | Junction to ambient |

| Operating Temp Range | 0°C to +125°C | Junction temperature |

Pin Configuration

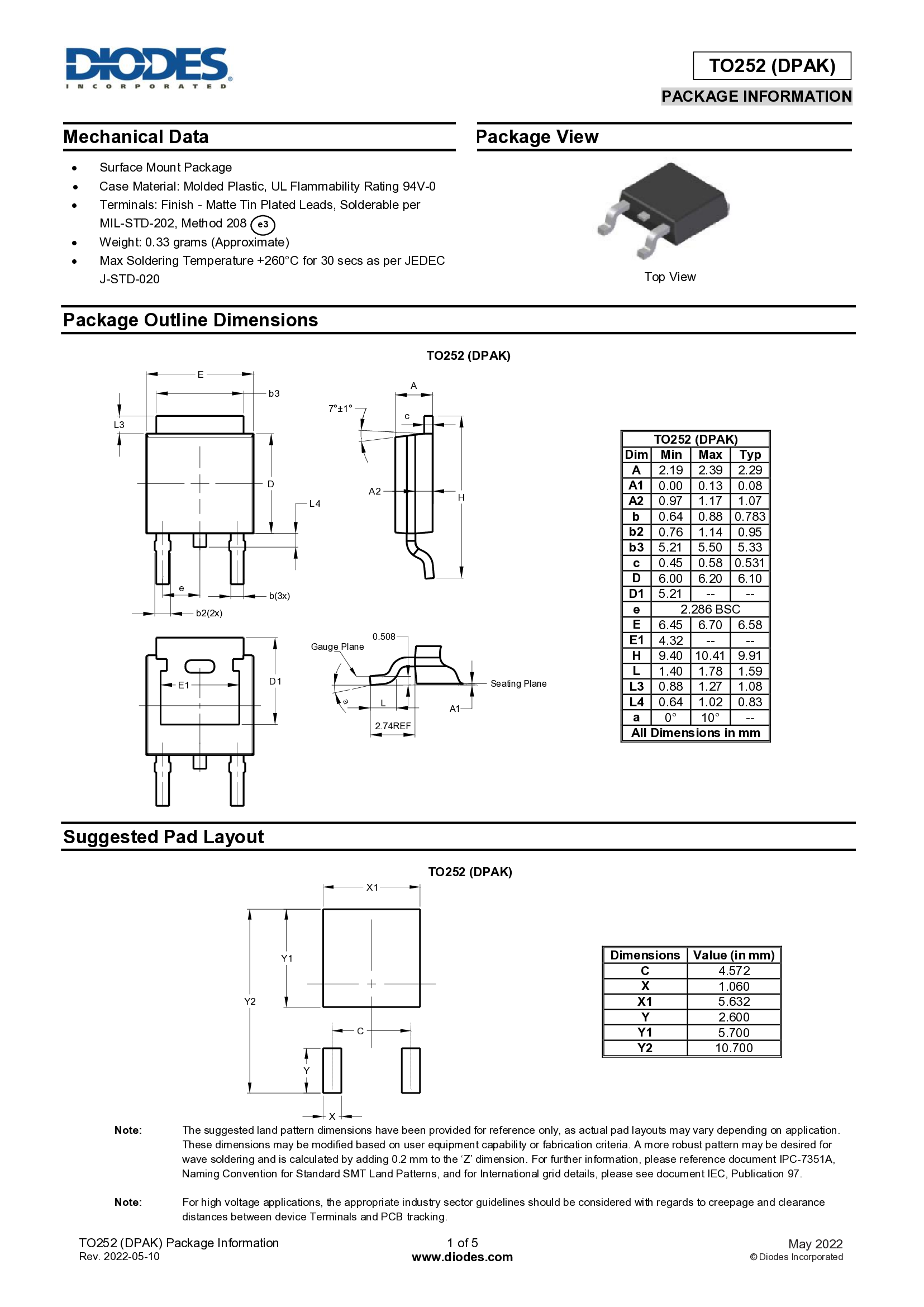

TO-252-2L (DPAK) Package

Top View

┌──────────────┐

│ │

│ CJ7912 │

│ │

│ │

│ │

└──┬───────┬───┘

│ │

PIN1 PIN2

GND INPUT

(Common) (-13.5V)

TAB

(OUTPUT)

(-12V)

Side View

┌──────────────┐

│ Component │ ← Surface mount IC

└──┬───────┬───┘

│ │

PIN1 PIN2

════════════════════ ← Metal tab (OUTPUT)

soldered to PCB pad

Pin Descriptions

| Pin | Name | Function | Connection in Design |

|---|---|---|---|

| 1 | GND | Ground reference (common) | System ground plane |

| 2 | INPUT | Unregulated input voltage | -13.5V from DC-DC converter (U4) |

| TAB | OUTPUT | Regulated -12V output (metal tab) | -12V rail with protection circuit |

Critical Note: This is a NEGATIVE voltage regulator. Pin numbering and voltage polarities are different from positive regulators:

- Pin 1 is GND (not INPUT like 78xx series)

- Pin 2 is INPUT (not GND like 78xx series)

- More negative voltage is "higher" voltage for this regulator

- Input must be more negative than output (-13.5V is "higher" than -12V)

Application Circuit

-13.5V (from DC-DC) ──┬─── C13: 470nF ───┬─── U8: CJ7912 ────┬─── C16: 100nF ───┬─→ -12V OUT

│ │ │ │

│ │ ┌──────────┐ │ │

│ └────│2 INPUT │ │ │

│ │ │ │ │

│ ┌──│1 GND │ │ │

│ │ │ │ │ │

│ │ │ TAB ───┴───┴──────────────────┤

│ │ └──────────┘ │

│ │ (OUTPUT) │

└─── C21: 470µF ─────┼─────────┬─── C22: 470µF ───────────┤

(Input) │ │ (Output) │

│ │ │

GND GND │

│

┌───────────────────────────────────────┘

│

┌─────┴─────┐

│ LED4 │ Red Status LED

│ (Red) │ via R9: 1kΩ

└─────┬─────┘

│

GND

Component Values

Input Capacitors

| Reference | Value | Type | Voltage | Package | Part Number | Purpose |

|---|---|---|---|---|---|---|

| C13 | 470nF | Ceramic X7R | 25V | 0603 | C1623 | High-frequency noise filtering |

| C21 | 470µF | Electrolytic | 25V | D10xL10.2mm | C3351 | Input voltage stabilization |

Important: For C21, negative terminal connects to -13.5V input, positive terminal connects to GND.

Output Capacitors

| Reference | Value | Type | Voltage | Package | Part Number | Purpose |

|---|---|---|---|---|---|---|

| C16 | 100nF | Ceramic X7R | 50V | 0805 | C49678 | High-frequency decoupling |

| C22 | 470µF | Electrolytic | 25V | D10xL10.2mm | C3351 | Load transient response |

Important: For C22, negative terminal connects to -12V output, positive terminal connects to GND.

Status LED Circuit

| Reference | Part | Value | Package | Part Number | Purpose |

|---|---|---|---|---|---|

| LED4 | Red LED | 2.0V @ 10mA | 0805 | C84256 | Power status indicator |

| R9 | Resistor | 1kΩ | 0603 | C21190 | LED current limiting |

LED Connection: Anode to GND, Cathode to -12V through R9 (reverse of positive rail LEDs).

Design Considerations

Negative Voltage Concepts

Understanding negative voltage regulators:

Voltage Levels (relative to GND = 0V):

GND (0V) ─────────────────

│

│ +13.5V "above" ground

│

+13.5V ─────────────────

GND (0V) ─────────────────

│

│ 12V "below" ground

│

-12V ─────────────────

│

│ 13.5V "below" ground

│

-13.5V ─────────────────

For negative regulator:

- INPUT = -13.5V (more negative)

- OUTPUT = -12V (less negative)

- Dropout = |VIN| - |VOUT| = 13.5V - 12V = 1.5V

Input Voltage Requirements

The CJ7912 requires input voltage to be at least 2V more negative than the output for proper regulation:

- Input voltage: -13.5V from LM2596S DC-DC converter

- Output voltage: -12V

- Dropout margin: 13.5V - 12V = 1.5V

- Status: ⚠️ Marginal - operates near minimum dropout voltage

The 1.5V margin is slightly below the typical 2V dropout specification but acceptable because:

- The DC-DC stage is regulated at -13.5V

- The CJ7912 can regulate with 1.5V dropout at lower currents

- Actual load current (0.8A) is well below maximum rating (1.5A)

- Negative regulators often have slightly lower dropout than positive equivalents

Recommendation: For production, consider increasing DC-DC output to -14.0V for better dropout margin.

Thermal Management

Power dissipation calculation:

P = (|VIN| - |VOUT|) × IOUT

P = (13.5V - 12V) × 0.8A

P = 1.5V × 0.8A

P = 1.2W

Temperature rise without additional heatsinking:

ΔT = P × θJA

ΔT = 1.2W × 40°C/W

ΔT = 48°C

At 25°C ambient, junction temperature = 73°C (well within 125°C maximum).

Thermal performance of TO-252-2L:

- Moderate θJA (40°C/W)

- Metal tab provides good heat spreading

- Direct thermal contact with PCB copper pour

- No additional heatsink required for this application

PCB copper area recommendations:

- Minimum: 3 cm² copper pour connected to tab

- Recommended: 6 cm² copper pour for better margin

- Thermal vias: 6-8 vias (0.3mm) under tab to bottom layer

Capacitor Placement and Polarity

Critical for negative regulators: Electrolytic capacitor polarity is REVERSED from what you might expect:

Correct polarity for negative rail:

C21 (Input, 470µF):

┌─────────┐

GND ───┤+ -├─── -13.5V

└─────────┘

C22 (Output, 470µF):

┌─────────┐

GND ───┤+ -├─── -12V

└─────────┘

REMEMBER:

- Positive terminal goes to GROUND (0V)

- Negative terminal goes to negative voltage

- This is OPPOSITE of positive voltage regulators

Placement guidelines:

-

C13 (470nF ceramic): Place within 5mm of pin 2

- Purpose: Suppress high-frequency noise from DC-DC stage

- Non-polarized, so no polarity concerns

-

C21 (470µF electrolytic): Place within 10mm of pin 2

- Purpose: Stabilize input voltage during load transients

- POLARITY: + to GND, - to -13.5V

-

C16 (100nF ceramic): Place within 5mm of output tab

- Purpose: High-frequency output decoupling

- Critical for preventing oscillation

-

C22 (470µF electrolytic): Place within 10mm of output tab

- Purpose: Improve load transient response

- POLARITY: + to GND, - to -12V

Ground Plane Connection

The TO-252-2L package layout:

- Pin 1 (GND): Wide connection directly to ground plane

- Pin 2 (INPUT): Connect to -13.5V rail

- Tab (OUTPUT): Large copper pour for -12V distribution and thermal management

- Thermal vias: Essential for heat dissipation to inner/bottom layers

Performance Characteristics

Regulation Performance

| Condition | Specification | Typical Performance |

|---|---|---|

| Line regulation | VIN = -14.5V to -27V | ±0.5% (±60mV) |

| Load regulation | IOUT = 5mA to 1.5A | ±1% (±120mV) |

| Output voltage accuracy | At 25°C | ±4% (±480mV) |

| Temperature coefficient | -40°C to +125°C | ±1mV/°C typical |

Noise Performance

| Parameter | Value | Conditions |

|---|---|---|

| Ripple rejection | 60dB min | f = 120Hz |

| Output noise voltage | <1mVp-p | With recommended capacitors |

| Transient response | <50µs | 400mA load step |

Protection Features

Built-in Protections

- Thermal Shutdown: Automatically shuts down if junction temperature exceeds 150°C

- Short Circuit Protection: Current limiting prevents damage during output short

- Safe Operating Area (SOA): Internal circuitry ensures operation within safe limits

External Protection (This Design)

-12V (from U8) ──┬─── PTC3: 1.1A ──┬─── F3: 1.5A ──┬─── TVS3: SMAJ15A ───┬─→ -12V OUT

│ (Auto-Reset) │ (Backup) │ (15V Clamp Rev) │

│ │ │ ↑ │

│ │ └─────GND─────────────┤

│ │ │

└─── LED4 (Red) via R9 (1kΩ) ──────────────→ Power Status

(Cathode to -12V, Anode to GND through resistor)

TVS Diode Connection for Negative Rail:

TVS3 (SMAJ15A)

┌─────┐

-12V ───────┤ │ ├────── GND

└──▲──┘

│

(Cathode to -12V

Anode to GND)

Protection stages:

- Overload (0.9A-1.5A): PTC3 trips → Auto-reset after cooling

- Short circuit (>1.5A): F3 blows → Manual replacement required

- Overvoltage: TVS3 clamps transients (reverse-biased for negative voltage)

Note: For the negative rail, the TVS diode is connected with cathode to -12V and anode to GND, which is reverse of positive rail configuration.

Bill of Materials

| Designator | Part | Value | Package | JLCPCB Part # | Qty | Unit Price | Extended |

|---|---|---|---|---|---|---|---|

| U8 | CJ7912 | Fixed -12V LDO | TO-252-2L | C94173 | 1 | $0.11 | $0.11 |

| C13 | Ceramic Cap | 470nF 25V X7R | 0603 | C1623 | 1 | $0.0036 | $0.0036 |

| C16 | Ceramic Cap | 100nF 50V X7R | 0805 | C49678 | 1 | $0.0021 | $0.0021 |

| C21, C22 | Electrolytic | 470µF 25V | D10xL10.2mm | C3351 | 2 | $0.044 | $0.088 |

| LED4 | LED | Red 0805 | 0805 | C84256 | 1 | $0.0126 | $0.0126 |

| R9 | Resistor | 1kΩ ±1% | 0603 | C21190 | 1 | $0.0005 | $0.0005 |

| Total | $0.22 |

Note: Higher total cost than positive regulators due to larger electrolytic capacitors (25V rating vs 10V).

Alternative Parts

Direct Replacements (TO-252-2L Package)

| Part Number | Manufacturer | JLCPCB Part # | Stock | Price | Notes |

|---|---|---|---|---|---|

| CJ7912 | Jiangsu Changjing Electronics | C94173 | 15,466 | $0.11 | Recommended (moderate stock) |

| LM7912DT | STMicroelectronics | Check | Check | ~$0.15 | Higher quality, better specs |

| MC7912DTG | ON Semiconductor | Check | Check | ~$0.14 | Pin-compatible |

Package Alternatives

| Package | Part Number | JLCPCB Part # | Stock | Price | Notes |

|---|---|---|---|---|---|

| TO-252-2L | CJ7912 | C94173 | 15,466 | $0.11 | Recommended (SMD) |

| TO-220 | L7912CV | C192101 | 3,386 | $0.11 | Through-hole alternative |

| SOT-89 | LM7912-SOT89 | Check | Lower | ~$0.18 | Lower current rating |

Stock Note: If C94173 (CJ7912) is out of stock, consider C192101 (L7912CV TO-220) which has similar availability.

PCB Layout Guidelines

Footprint Requirements

TO-252-2L (DPAK) package footprint specifications:

Top View (PCB Pad Layout)

┌──────────────────────────────┐

│ │

│ Large Copper Pour │ ← OUTPUT TAB (-12V)

│ (6cm² recommended) │ thermal + electrical

│ │

│ Thermal Vias │

│ (6-8 vias) │

│ │

└──────────────────────────────┘

PIN1 ■ PIN2 ■

(GND) (INPUT)

(-13.5V)

Pin spacing: 2.28mm

Pin pad: 1.5mm x 2.0mm

Tab pad: 10mm x 10mm (minimum)

12mm x 12mm (recommended)

Recommended Pad Dimensions

| Pad | Width | Length | Purpose |

|---|---|---|---|

| Pin 1 (GND) | 2.0mm | 3.0mm | Larger for ground connection |

| Pin 2 (INPUT) | 1.5mm | 2.0mm | Solder pad for input pin |

| Tab (OUTPUT) | 10-12mm | 10-12mm | Thermal and electrical connection |

Layout Recommendations

-

Component placement:

- Orient IC with tab facing interior of PCB

- Maximize copper area under and around tab for -12V rail

- Keep input and output capacitors on same side as regulator

- Separate -12V copper pour from +12V pour (clearance >2mm)

-

Copper pours:

- Create dedicated copper pour for -12V rail (6cm² minimum)

- Top layer: Main output pad and distribution to -12V loads

- Bottom layer: Additional copper connected via thermal vias

- Keep -12V copper separate from positive voltage pours

-

Thermal vias:

- Place 6-8 thermal vias (0.3mm diameter) under tab

- Arrange in grid pattern for even heat distribution

- Connect to bottom layer copper pour for -12V

- Direct connection (no thermal relief) for best heat transfer

-

Trace widths:

- Input trace (-13.5V): 0.8mm minimum (0.8A current)

- Output trace (-12V): 1mm minimum (0.8A current)

- Ground: Maximum copper pour area

- High-current paths: 2mm or copper pour preferred

-

Electrolytic capacitor polarity markings:

- Add clear silkscreen markings: "+" toward GND

- Add polarity indicators to prevent assembly errors

- Consider adding text: "NEG RAIL - CHECK POLARITY"

Critical Layout Warnings

⚠️ ELECTROLYTIC CAPACITOR POLARITY WARNING ⚠️

For negative voltage regulator:

Positive terminal (+) → GND (0V)

Negative terminal (-) → Negative voltage

This is OPPOSITE of positive regulators!

Add clear silkscreen markings to prevent

assembly errors that will destroy capacitors.

Thermal Via Pattern

Recommended thermal via pattern

under TO-252-2L tab:

┌─────────────────────────┐

│ │

│ ● ● ● ● ● │

│ │ ← 0.3mm vias

│ ● ● ● ● ● │ 2.5mm spacing

│ │

└─────────────────────────┘

Total vias: 10 (aggressive cooling)

Minimum: 6 vias

Recommended: 8 vias

Assembly Considerations

Critical Assembly Warnings

ELECTROLYTIC CAPACITOR POLARITY:

The most common assembly error with negative voltage regulators is installing electrolytic capacitors backwards. This will cause:

- Immediate capacitor failure

- Possible explosion of electrolytic capacitors

- Regulator damage

- Board contamination

Prevention:

- Add clear silkscreen markings on PCB

- Include assembly notes in BOM

- Test capacitor polarity with DMM before powering

- Use polarized ceramic capacitors if available (more expensive)

Soldering Guidelines

Reflow soldering (recommended for production):

- Peak temperature: 260°C maximum

- Time above 220°C: 60-90 seconds

- Solder paste: SAC305 or similar lead-free

- Stencil thickness: 0.125mm (5 mil)

Hand soldering:

- Soldering iron: 350°C maximum

- Solder pin 1 (GND) first for reference

- Solder pin 2 (INPUT) second

- Apply solder to tab from component side

- Ensure good thermal contact between tab and PCB pad

Inspection Points

After assembly, inspect:

- Electrolytic capacitor polarity: CRITICAL - verify + to GND

- Pin solder joints: Smooth fillet, no bridges

- Tab solder joint: Good coverage, no voids

- Component alignment: Centered on pads

- Thermal via filling: Solder should wick into vias

Pre-power checklist:

- C21 polarity: + terminal to GND, - terminal to -13.5V

- C22 polarity: + terminal to GND, - terminal to -12V

- Visual inspection complete

- Continuity test: GND to pin 1

- Resistance test: No shorts between -12V and GND

- Resistance test: No shorts between -13.5V and GND

Testing and Validation

Pre-Power Inspection

Before applying power, verify:

-

Capacitor polarity check:

- C21: Measure with DMM in diode mode

- C22: Measure with DMM in diode mode

- Positive terminal should be at GND potential

- Negative terminal should be connected to negative voltage rail

-

Visual inspection:

- No solder bridges

- Good solder joints on tab

- Correct IC orientation

- All components present

Initial Power-Up Test

-

Apply input voltage slowly:

- Start with -10V input (below regulation threshold)

- Gradually increase to -13.5V

- Monitor for smoke or unusual smells

- Check for thermal runaway

-

No-load test:

- Apply -13.5V to input

- Verify output voltage: -11.52V to -12.48V (-12V ±4%)

- Measure quiescent current: <10mA

- Check case temperature: Should be near ambient

Load Regulation Test

- Connect variable load (0-1.0A)

- Measure output voltage at different load currents:

- 0mA: Should be within -12V ±2%

- 400mA: Should be within -12V ±3%

- 800mA: Should be within -12V ±4%

- Verify voltage variation <120mV from no-load to full-load

Thermal Test

- Apply 0.8A load for 30 minutes

- Measure case temperature with thermal camera

- Verify case temperature <75°C at 25°C ambient

- Compare to calculation: Should be ~73°C

- Check for thermal shutdown (should not occur)

Ripple and Noise Test

- Connect oscilloscope (AC coupling, 20MHz bandwidth limit)

- Use short ground lead or coax probe

- Measure output relative to GND with 0.8A load

- Verify peak-to-peak ripple <5mVp-p (target: <1mVp-p)

- Check for oscillation or instability

Transient Response Test

- Use electronic load with step function (0A → 0.8A)

- Monitor output voltage on oscilloscope

- Verify voltage dip <200mV during load step

- Verify recovery time <100µs

- Check for ringing or overshoot

Troubleshooting

| Symptom | Possible Cause | Solution |

|---|---|---|

| No output voltage | Input voltage not negative enough | Verify -13.5V input from DC-DC |

| Shorted output | Check for shorts on -12V rail | |

| Electrolytic cap installed backwards | CHECK POLARITY - replace if backwards | |

| Thermal shutdown | Reduce load, check thermal vias | |

| Smoke/burning smell | Electrolytic cap reversed | POWER OFF IMMEDIATELY - replace cap |

| Output shorted to ground | Remove short, check board | |

| Low output magnitude | Insufficient input voltage | Check DC-DC output (should be -13.5V) |

| (e.g., -10V instead of -12V) | Excessive load current | Verify load <0.8A |

| Poor ground connection | Check pin 1 connection | |

| High ripple noise | Missing input capacitor | Verify C13, C21 installed |

| Missing output capacitor | Verify C16, C22 installed | |

| Wrong capacitor polarity | Check electrolytic polarity | |

| Oscillation | Missing C16 (100nF output) | Add C16 close to output tab |

| Long output traces | Shorten traces, add local decoupling | |

| Capacitive load | Add series resistance (1Ω) at output | |

| Overheating | Excessive power dissipation | Check input voltage (should be -13.5V) |

| Insufficient copper area | Increase copper pour under tab | |

| No thermal vias | Add thermal vias under tab | |

| Poor thermal contact | Check solder joint on tab | |

| Wrong polarity output | Wrong regulator installed | Verify CJ7912 not CJ7812 |

| (+12V instead of -12V) | Wiring error | Check schematic vs. layout |

| Voltage too negative | Input voltage too negative | Check DC-DC stage (-13.5V target) |

| (e.g., -13V instead of -12V) | Wrong feedback resistors on DC-DC | Check U4 feedback network |

Application Notes

Op-Amp Power Supply Considerations

The -12V rail typically powers operational amplifiers in modular synthesizers:

Typical op-amp requirements:

- Dual supply: ±12V (some designs use ±15V)

- Current per op-amp: 2-10mA quiescent

- Peak current: Up to 30mA during output swings

- Noise sensitivity: Very high (audio applications)

Distribution recommendations:

-

Star ground topology:

- Connect all op-amp ground pins to single point

- Prevents ground loops and noise coupling

- Keep analog ground separate from digital ground

-

Local decoupling:

- Add 100nF ceramic capacitor at each op-amp power pin

- Place capacitor within 5mm of IC

- Both +12V and -12V pins need decoupling

-

Bulk capacitance:

- Add 10µF electrolytic per 4-8 op-amps

- Place in central location

- Remember polarity: + to GND, - to -12V

Audio Noise Considerations

For ultra-low-noise audio applications:

-

Additional filtering:

- Add RC filter: 10Ω + 47µF per audio section

- Creates pole at ~340Hz

- Reduces regulator noise in audio band

-

Separate analog/digital -12V:

- Use separate regulators if possible

- If sharing regulator, use isolation filters

- Prevents digital switching noise coupling to audio circuits

-

PCB layout:

- Keep -12V traces away from high-frequency signals

- Use ground plane as shield

- Route audio signals perpendicular to power traces

Dual Supply Voltage Matching

When using ±12V supplies for op-amps, voltage matching is important:

| Parameter | Specification | Impact |

|---|---|---|

| Voltage match | Within ±0.5V | Prevents DC offset in op-amp outputs |

| Noise match | Within 2:1 ratio | Balanced noise rejection |

| Regulation match | Within ±1% | Consistent performance across temperature |

Verification:

- Measure both +12V and -12V outputs simultaneously

- Calculate: |V+12| - |V-12| should be <0.5V

- Adjust DC-DC stage if needed (modify feedback resistors)

Related Components

- Upstream: LM2596S-ADJ (U4) - Provides -13.5V input via inverting buck-boost topology

- Downstream: Protection circuit (PTC3, F3, TVS3)

- Parallel regulators: L7812CD2T-TR (U6), L7805ABD2T-TR (U7)

Common Mistakes and How to Avoid Them

Mistake 1: Reversed Electrolytic Capacitors

Problem: Installing C21 or C22 with reversed polarity Consequence: Capacitor explosion, regulator damage Prevention:

- Add large silkscreen warnings on PCB

- Test polarity with DMM before powering up

- Use checklist during assembly

Mistake 2: Confusing Positive and Negative Regulator Pinouts

Problem: Assuming pin 1 is INPUT (like 78xx series) Consequence: Wrong connections, no output Prevention:

- Clearly label pins on schematic: "Pin 1 = GND" not "Pin 1"

- Add reference designator table to schematic

- Use different symbol for negative regulators

Mistake 3: Insufficient Dropout Voltage

Problem: Input voltage not negative enough (-12V input for -12V output) Consequence: No regulation, output follows input Prevention:

- Calculate dropout: |VIN| must be >|VOUT| + 2V

- Design DC-DC stage for -13.5V or -14V

- Monitor DC-DC output voltage during testing

Mistake 4: Wrong TVS Diode Polarity

Problem: Installing TVS3 with cathode to GND (like positive rail) Consequence: No overvoltage protection, possible short circuit Prevention:

- Clearly mark TVS polarity on schematic

- For negative rail: Cathode to negative voltage, Anode to GND

- Test TVS connection with DMM (should show high resistance GND to -12V)

Mistake 5: Shared Copper Pour with Positive Rails

Problem: Connecting -12V copper to +12V copper Consequence: Direct short circuit, catastrophic failure Prevention:

- Use separate copper pours for each voltage rail

- Maintain >2mm clearance between different voltage pours

- Use DRC (Design Rule Check) to verify clearances

References

- CJ7912 Datasheet - Jiangsu Changjing Electronics

- JLCPCB Part C94173

- Negative Voltage Regulator Application Note - Texas Instruments

- LM79xx Series Datasheet - General reference for 79xx series

- Related documentation: Diagram7 - -12V Linear Regulator